Alinda Oyku Akar

Ravago R&D Center, Turkey

Title: Investigations on properties of polyhedral oligomeric silsesquioxane (POSS) and halloysites nanotubes (HNT) reinforced polyurethane elastomer hybrid nano-composites

Biography

Biography: Alinda Oyku Akar

Abstract

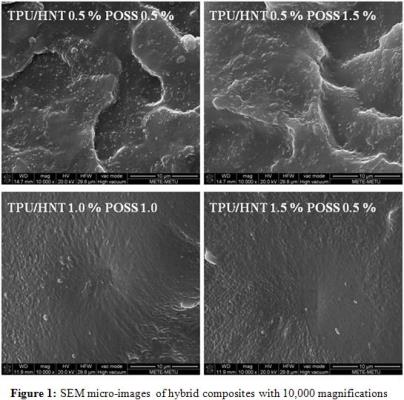

The improvement of various properties of polyurethane elastomer-thermoplastic polyurethane (TPU) is still of great interest for scientists and researchers due to the expansion of its application areas. In this study, TPU matrix was reinforced with polyhedral oligomeric silsesquioxane (POSS) and halloysites nanotubes (HNT) by addition of them as separately and in hybrid forms. The preparation of composites was carried out using a lab-scale micro-compounder with the loading ratios from 0.5 wt% to 2.0 wt%. The test samples were prepared using injection-molding. As for TPU/POSS/HNT hybrid composites, the loading percentages were (0.5%, 0.5%), (1.0%, 1.0%), (0.5%, 1.5%), and (1.5%, 0.5%). Mechanical, damping, tribological, melt flow and morphological properties of TPU based composites were reported by performing tensile and hardness test, dynamic mechanical analysis (DMA), abrasion resistance test, melt flow index test, and scanning electron microscopy (SEM) methods, respectively. The mechanical properties are improved with the incorporations of HNT and POSS nanoparticles as their both individual and hybrid forms which were revealed by tensile test. HNT and POSS additions at their lowest loading ratios (0.5%) level up the tensile strength of TPU to nearly 20% and 12% higher values, respectively. Further additions of these fillers cause reductions for strength values of composites. No remarkable differences are observed in percent elongation and elastic modulus of TPU after HNT and POSS inclusions. Shore hardness of unfilled TPU slightly increases with the incorporation of the HNT and POSS. According to DMA analysis, the highest loss modulus is observed for 1.0% POSS loaded composite. HNT and POSS containing composites yield higher values in tan δ for the lowest filling ratios. As the SEM micrographs of selected composites examined, formations of agglomerates are observed for higher loading level of HNT and POSS nanoparticles. Homogeneity of their mixing in TPU matrix decreases as the concentrations of POSS and HNT increase. As a comparison, HNT containing composites exhibit slightly higher values over POSS filled composites. This greater reinforcing effect of 1D structured HNT may stem from its larger surface area and aspect ratio relative to POSS with particulate structure.