Gabriel Gaal

University of Campinas, Brazil

Title: Fabrication of conductive trails using 3D printing technology

Biography

Biography: Gabriel Gaal

Abstract

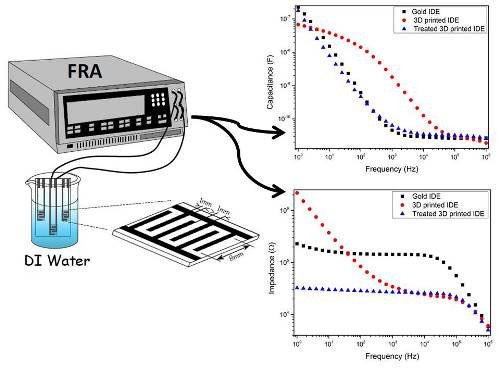

Nowadays, one of the biggest issues addressed to sensor fabrication is build up efficient electrodes as an alternative to the complex and expensive processes required by traditional techniques. Within this context, printed electronics arises as an interesting alternative due its simplicity and robustness to put electrodes on various surfaces. Fused Deposition Modeling (FDM) 3D printing can be widely explored as a cheap and accessible technology to fabricate electrodes. We show here the fabrication of fully 3D printed interdigitate electrodes (IDE) using a home-made FDM 3D printer and a commercial graphene-based PLA filament. We used a standard home-made 3D printer (Mendel90) with a commercial hot nozzle of 0.4 mm in diameter to extrude transparent PLA at 200ºC and a graphene-based PLA at 175ºC. The molten filament is further deposited on a hot bed (60ºC) having 200mm x 200 mm, using a mirror as the heated platen to ensure a flat and smooth printing surface. Extruder and hot table are moved by stepper motors following Cartesian coordinates, printing the object in a layer-by-layer process. The 3D printed IDEs were easily assembled within 6 minutes, and their frequency responses on aqueous medium were compared with traditional gold IDEs fabricated through microfabrication technique. Furthermore, we proposed a surface treatment with a solution of H2SO4 + KMnO4, and we observed a huge enhancement of the IDE response. Conductive tracks 3D printed with a graphene-based PLA enabled a rapid prototyping and reduction in the steps for the fabrication process of IDEs which could be assembled in a few minutes. A good electrical response was obtained via surface treatment recovering the gold IDE frequency response on aqueous media. Finally, 3D printing technology potentiates several fields with more creative ideas, cost-effective and alternative materials for a rapid prototyping of complex devices, paving the way to more abundant developments.

Comparison of the real capacitance and impedance modulus frequency response of gold IDE, fully 3D printed IDE and another fully 3D printed IDE treated with sulfuric acid and potassium permanganate. We measured the frequency response of the IDEs with a commercial frequency response analyzer (Solartron). The measurements were taken within an aqueous medium.